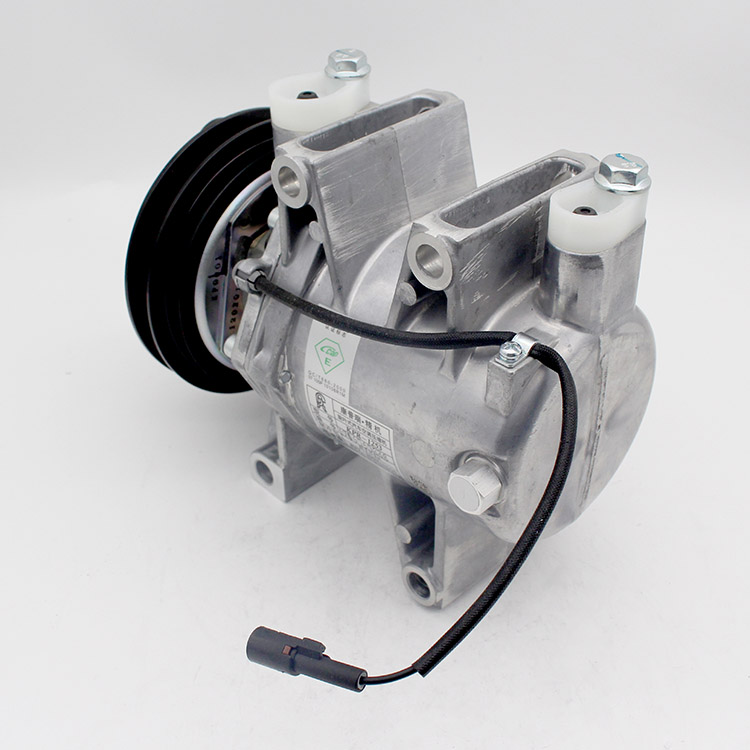

KPR-1253 12V Auto Ac Compressors Manufacturer For Isuzu D-max / Isuzu Mixer Truck / Isuzu Tractor

The compressor must be labeled as required and packed in a specially designed corrugated carton.

Before packaging, the compressor is evacuated and then filled with (0.049~0.088) MPa industrial nitrogen.

The certificate of product should be enclosed in the packing box, and the product for retail should be accompanied by instructions for use and installation.

It should be handled with care during transportation. It do not drop, exposed to rain, or exposed to the sun, and it is not allowed to damage the compressor in the box.The storage environment should be dry and ventilated and there should be no corrosive gas around.

The suction and exhaust plug of the compressor can be removed only when the compressor is in use. If the suction and exhaust plug falls off or loosens, it should be checked and handled in time.

1.Keep pressure after vacuuming

2.The car is running at idle speed

3.Flush gas refrigerant from the suction port at low pressure

4.The mouth of the refrigerant tank is upward

5.Prevent the compressor from being filled with liquid refrigerant to damage internal parts

6.The charging amount of refrigerant should be charged according to the requirements of the car factory

7.It can also be judged by the suction and exhaust pressure parameters

8.The suction port (low pressure) pressure is 0.2~0.3MPa

9.Exhaust port (high pressure) pressure 1.4~1.7MPa

10.Strictly control the torque of compressor mounting bolts and belt tension

11.The recommended specifications are torque value of M8 bolt: 25±2Nm and belt tension: 700±100N

Part Type: A/C Compressors

Box Dimensions: 250*220*200MM

Product weight: 5~6KG

Delivery Time: 20-40 Days

Warranty: Free 1 Year Unlimited Mileage Warranty

| Model NO | KPR-1253 |

| Application | Isuzu D-max 2.5 2012 |

| Voltage | DC12V |

| OEM NO. | 8981028240 / 8981028241 / 9260000C81 / 92600A070B |

| Pulley parameters | A φ125 |

Conventional carton packing or custom color box packing.

Assembly shop

Machining workshop

Mes the cockpit

The consignee or consignor area

Service

Customized service: We are able to meet the requirements of our customers, whether a small batch of multiple varieties, or a mass production of OEM customization.

OEM/ODM

1. Assist customers to make system matching solutions.

2. Provide technical support for products.

3. Assist customers to deal with after-sales problems.

1. We have been producing auto air conditioning compressors for more than 15 years.

2. Accurate positioning of the installation position, reduce deviation, easy to assemble, installation in one step.

3. The use of fine metal steel, a greater degree of rigidity, improve the service life.

4. Sufficient pressure, smooth transportation, improve power.

5. When driving at high speed, the input power is reduced and the engine load is reduced.

6. Smooth operation, low noise, small vibration, small starting torque.

7. 100% inspection before delivery.

AAPEX in America

Automechanika Shanghai 2019

CIAAR Shanghai 2019