High definition Bmw Ac Compressor - 12V Auto A/C Compressor Manufacture Factory For Subaru Impreza / Subaru Stella / Subaru Impreza XV – Hollysen

High definition Bmw Ac Compressor - 12V Auto A/C Compressor Manufacture Factory For Subaru Impreza / Subaru Stella / Subaru Impreza XV – Hollysen Detail:

The automobile air conditioning compressor is the heart of the automobile air conditioning system, which plays the role of compressing and conveying refrigerant steam. AC compressors are divided into two kinds: non-variable and variable displacement. Air conditioning compressor can be divided into fixed displacement compressor and variable displacement compressor according to the different working principle.

The displacement of the fixed displacement compressor is proportional to the increase of the engine speed, it can’t automatically change the power output according to the demand of refrigeration and the impact on the engine fuel consumption is relatively large. It is controlled by collecting the temperature signal of the outlet of the evaporator. When the temperature reaches the set temperature, the electromagnetic clutch of the compressor is released and the compressor stops working. When the temperature rises, the electromagnetic clutch is combined and the compressor begins to work. The constant displacement compressor is also controlled by the pressure of the air conditioning system. When the pressure in the pipeline is too high, the compressor stops working.

The variable displacement compressor can automatically adjust the power output according to the set temperature. The air conditioning control system doesn’t collect the temperature signal of the evaporator air outlet, but automatically adjusts the air outlet temperature by controlling the compression ratio of the compressor according to the change signal of the pressure in the air conditioning pipeline. During the whole process of refrigeration, the compressor is always working, and the adjustment of refrigeration intensity is completely dependent on the pressure regulating valve installed inside the compressor to control. When the pressure at the high pressure end of the air conditioning pipeline is too high, the pressure regulating valve shortens the piston stroke in the compressor to reduce the compression ratio, which will reduce the cooling strength. When the pressure at the high pressure end drops to a certain extent and the pressure at the low pressure end rises to a certain extent, the pressure regulating valve increases the piston stroke to improve the cooling strength.

Part Type: A/C Compressors

Box Dimensions: 250*220*200MM

Product weight: 5~6KG

Delivery Time: 20-40 Days

Warranty: Free 1 Year Unlimited Mileage Warranty

PRODUCT PARAMETERS

|

Model NO |

KPR-8354 |

|

Application |

Subaru Impreza WRX 2006 |

|

Voltage |

DC12V |

|

OEM NO. |

73111FE030 / A4201101A00003 |

|

Pulley parameters |

4PK/φ124.5MM |

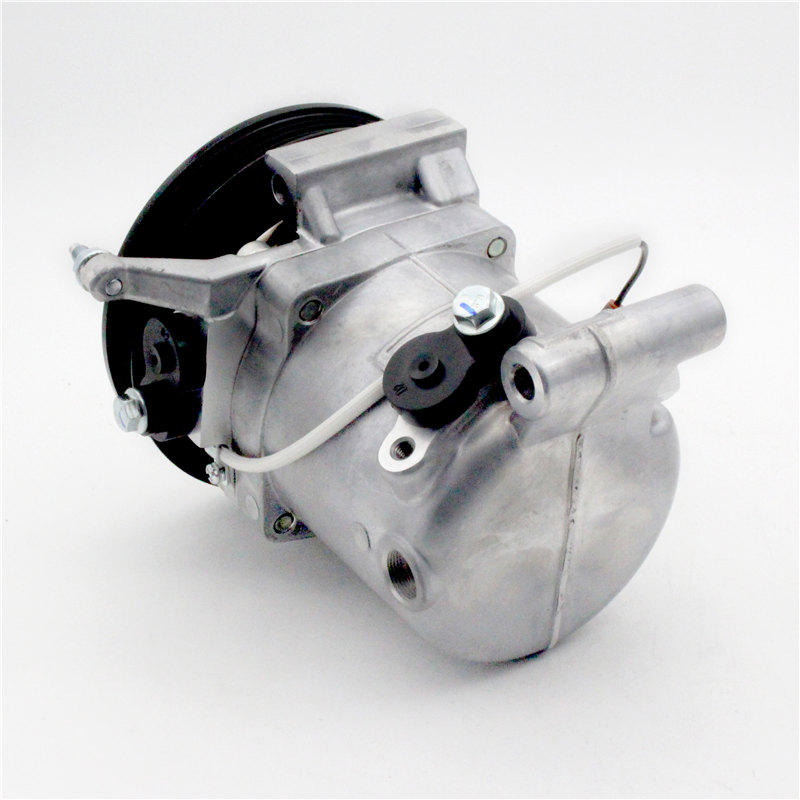

Product picture

Product parameters

|

Model NO |

KPR-8365 |

|

Application |

Subaru Stella/R2 |

|

Voltage |

DC12V |

|

OEM NO. |

73111KG010 / A42011A2501001 |

|

Pulley parameters |

4PK/φ110MM |

Product picture

Product parameters

|

Model NO |

KPR-1102 |

|

Application |

Subaru Impreza XV 1.6B-2.0B ’13->… / Subaru Impreza XV 2.5L ’12->’13 (6pk) |

|

Voltage |

DC12V |

|

OEM NO. |

73111FJ000 / Z0014247A / Z0014247B / 73111FJ010 / Z0014248B / 73111-FJ040 / Z0014247B / Z0021226A / DKV-10Z / Z001424713 |

|

Pulley parameters |

6PK/φ110MM |

Product picture

Packaging &shippment

Conventional carton packing or custom color box packing.

Produt video

Factory pictures

Assembly shop

Machining workshop

Mes the cockpit

The consignee or consignor area

Our Service

Service

Customized service: We are able to meet the requirements of our customers, whether a small batch of multiple varieties, or a mass production of OEM customization.

OEM/ODM

1. Assist customers to make system matching solutions.

2. Provide technical support for products.

3. Assist customers to deal with after-sales problems.

Our Advantage

1. We have been producing auto air conditioning compressors for more than 15 years.

2. Accurate positioning of the installation position, reduce deviation, easy to assemble, installation in one step.

3. The use of fine metal steel, a greater degree of rigidity, improve the service life.

4. Sufficient pressure, smooth transportation, improve power.

5. When driving at high speed, the input power is reduced and the engine load is reduced.

6. Smooth operation, low noise, small vibration, small starting torque.

7. 100% inspection before delivery.

Project Cases

AAPEX in America

Automechanika Shanghai 2019

CIAAR Shanghai 2020

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for High definition Bmw Ac Compressor - 12V Auto A/C Compressor Manufacture Factory For Subaru Impreza / Subaru Stella / Subaru Impreza XV – Hollysen , The product will supply to all over the world, such as: Japan, Manila, Russia, Now, we professionally supplies customers with our main merchandise And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.