Science Popularization | Detailed Introduction to Auto Air Conditioning Compressors:Types, Applications, and Structures (with Shipment Record)

Shipment Record on October 10

Helisheng successfully completed a batch of compressor shipments, marking another strong testament to our team’s hard work and exceptional capabilities. It also reflects our commitment to fulfilling customer promises and demonstrating the strength of our enterprise.

Company Overview

Changzhou HOlicen New Energy Technology Co., Ltd. is an independent development-oriented enterprise integrating R&D, production, and sales. We specialize in the manufacturing of parking air conditioners, parking heaters, automotive air conditioning compressors, and other related products.

We are committed to customer-oriented principles, constantly innovating technology and optimizing products. By strictly controlling product quality, we ensure that our offerings meet market demands. Our products are exported to Europe, America, the Middle East, Southeast Asia, South America, and Australia.

If you are interested in any of the above products, please scan the QR code on the homepage or contact us directly via phone or email! Up next, we will provide a detailed explanation of the professional knowledge about automotive air conditioning compressors.

——————————————————————————————————————————————————————————————————————————

Introduction to Automotive Air Conditioning Compressors

The automotive air conditioning compressor is the core component of the air conditioning refrigeration system. As demand for automotive comfort continues to rise, various new air conditioning systems have emerged, driving advancements in compressor manufacturing technology.

Currently, compressor technology is evolving toward compact structures, energy efficiency, low noise, and low vibration.

Based on operation methods and development history, automotive air conditioning compressors can be classified into four main types:

——————————————————————————————————————————————————————————————————————————

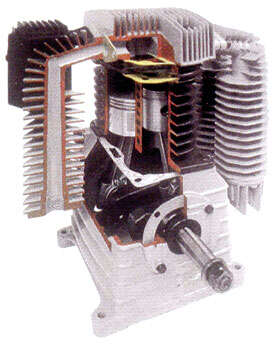

1. Crankshaft Connecting Rod Compressor

- Features: The first-generation air conditioning compressor, historically the earliest application, now phased out.

- Classification:

- By cylinder arrangement: Inline, V-shaped, W-shaped, S-shaped (rare).

- By cylinder count: 2, 4, 6, 8 cylinders.

- Advantages:Working Principle: The crankshaft and connecting rod rotate under the clutch’s drive, moving pistons through a cycle of compression, exhaust, expansion, and intake.

- Mature technology and simple structure.

- Lower processing requirements for components and reduced manufacturing costs.

——————————————————————————————————————————————————————————————————————————

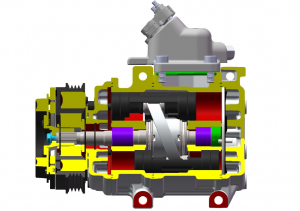

2. Axial Piston Compressor

- Features: Second-generation air conditioning compressor, widely used in various vehicle types.

- Classification:

- By drive structure: Single swashplate and dual swashplate.

- By cylinder count: 5, 6, 7, 10, 14 cylinders.

- Advantages:

- Mature technology, compact design, and low manufacturing costs.

- Wide displacement range, suitable for multiple vehicle types.

- Applications:

- Single Swashplate: High reliability for harsh conditions, commonly used in trucks and construction vehicles.

- Dual Swashplate: More suitable for lightweight, compact, high-speed, and efficient applications in passenger vehicles.

——————————————————————————————————————————————————————————————————————————

3. Rotary Vane Compressor

- Features: Third-generation air conditioning compressor.

- Classification:

- By cylinder shape: Circular, elliptical.

- By vane count: 2, 4, 6 vanes, etc.

- Advantages:

- Compact and lightweight, ideal for limited spaces.

- High speed, high efficiency, and low noise.

——————————————————————————————————————————————————————————————————————————

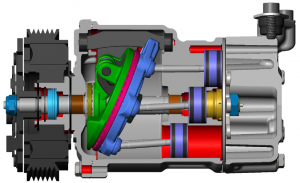

4. Scroll Compressor

- Features: Fourth-generation air conditioning compressor, widely applied in small refrigeration fields.

- Classification: Fixed-scroll and double-orbit designs, with the fixed-scroll type being most common.

- Advantages:

- Lightweight and capable of high rotational speeds.

- High reliability, excellent energy efficiency, low noise, and fewer components.

Conclusion

The development of automotive air conditioning compressors has evolved from simple designs to high-performance, compact solutions. Selecting the right compressor based on vehicle type, operating conditions, and performance requirements can significantly enhance the efficiency and comfort of air conditioning systems.

For further inquiries and product purchases, please contact Helisheng’s customer service. We are dedicated to serving you!

Post time: Dec-12-2024